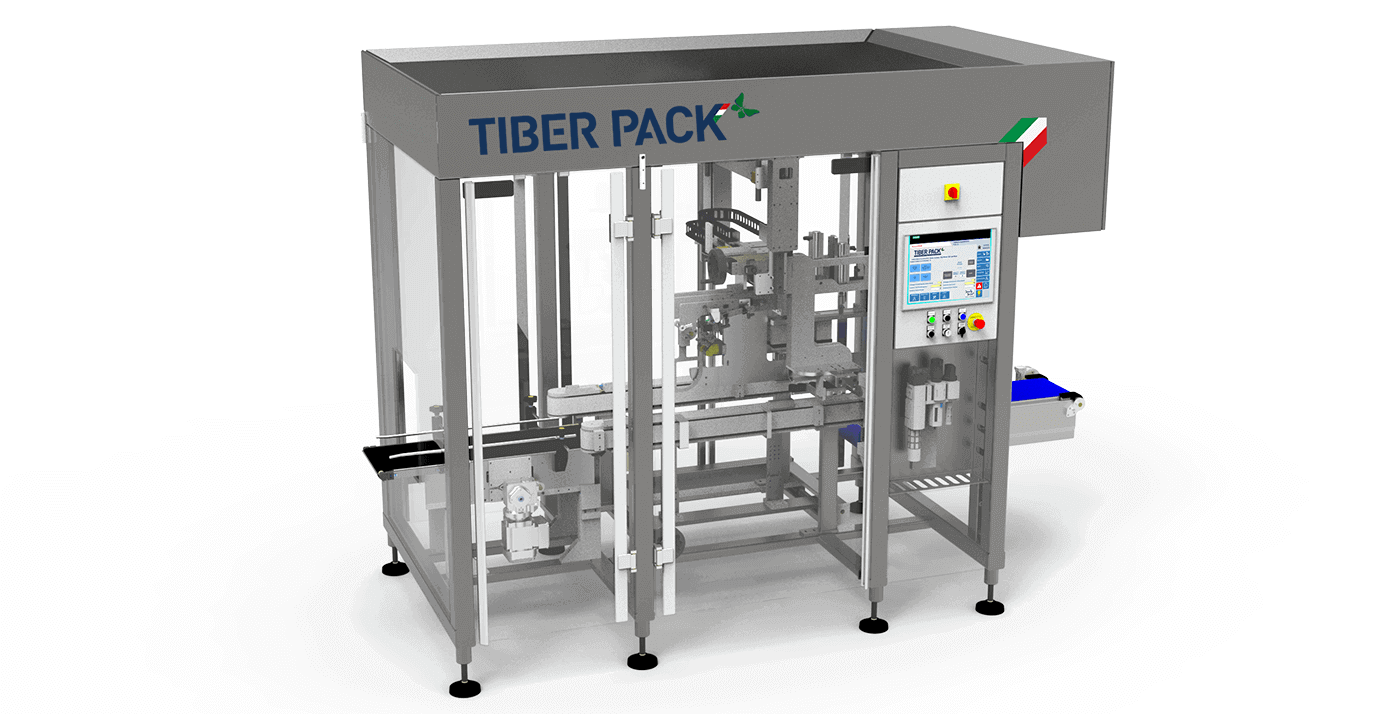

Sealing unit for standard (american) cases

- Very compact and versatile, can process a wide range of carton sizes

- May be supplied as a stand-alone module or used to form complete packaging lines when combined with forming and filling modules

DESCRIPTION

The SN/SH closing units have been designed for use in demanding operating conditions and are intended principally for installation on complete packaging lines operating on a 24/7 basis.

The units consist of painted steel frame and are equipped with Siemens or Allen Bradley electronic units and the same Festo pneumatic components used on all the Tiber Pack range of products. Thanks to the dual chain carton feeder system and motorised (SH series) aligning devices, the unit may be used to produce high quality packaging.

As well as their ergonomic design and intuitive 15” HMI panel, they also come with a wide range of accessories.

The SN series is equipped with an upper tape sealing system, while the SH series uses a hot-melt system.

The SN/SH series sealing units may also be equipped with automatic size changeover and can be combined with other modules to form a complete packaging line.

ADVANTAGES

- Reduced footprint

- Hot-melt or PVC tape upper flap closure

- Hygienic design

- Automatic, tool-less size changeover

- Standard 15” control panel with 3D graphics

- Customisable upon request

- Available with a wide range of additional modules

TECHNICAL SPECIFICATIONS

TECHNICAL DATA – SPECIFICATIONS

| Case Dimensions (LxWxH) | Min 190x150x110 – Max 600x400x350 |

| Sealing mode | – Hot-Melt – Tape |

| Capacity | Up to 22 cases/minute |