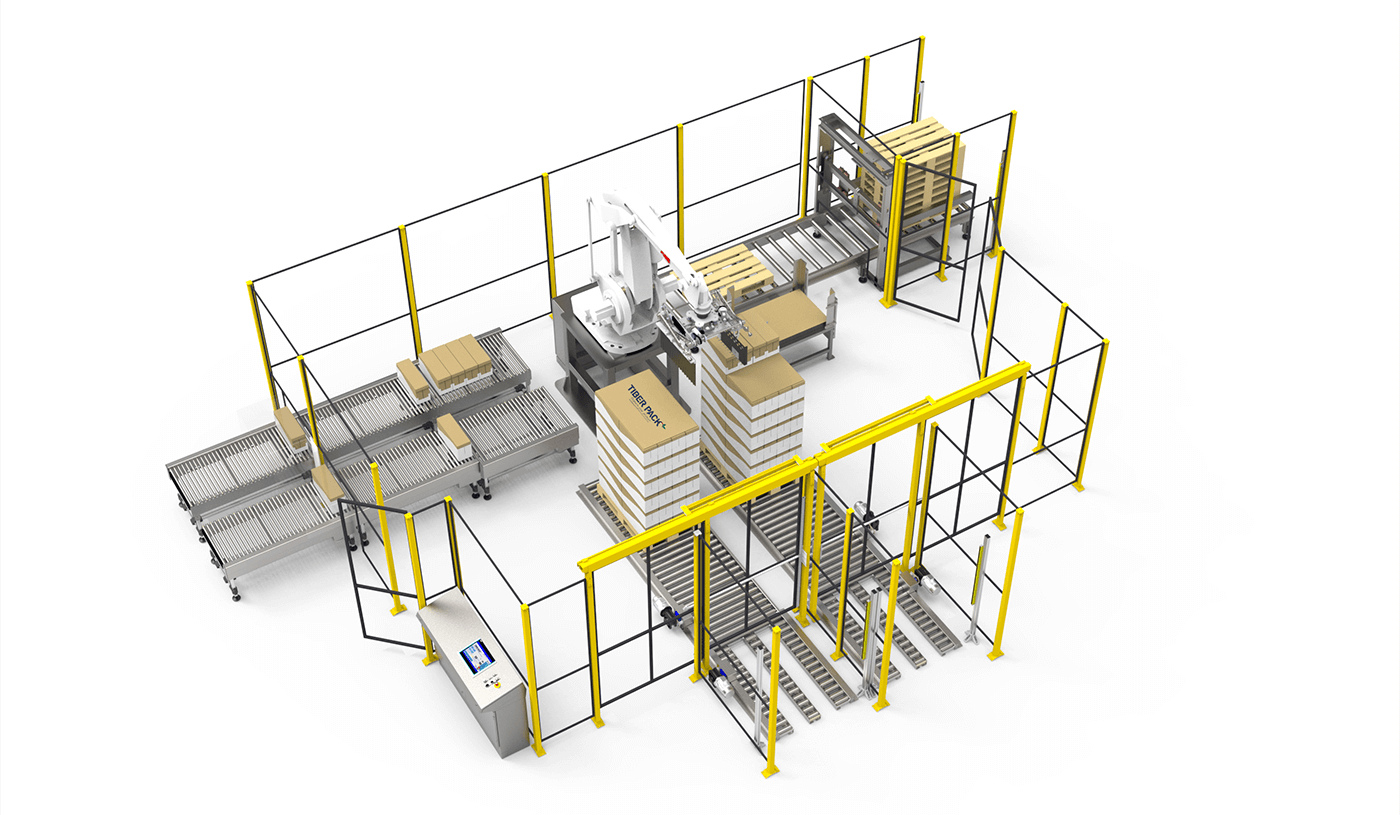

Palletisers with Anthropomorphic robots

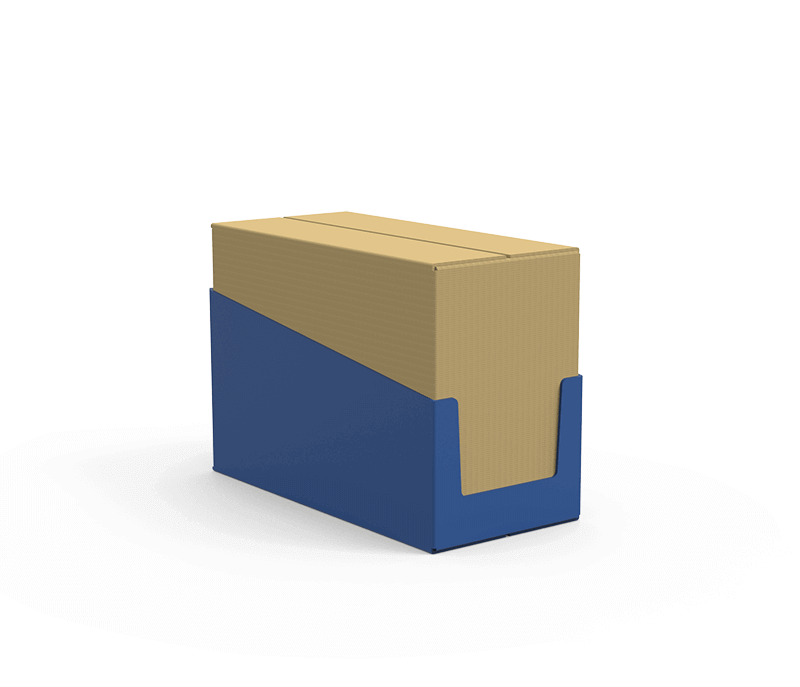

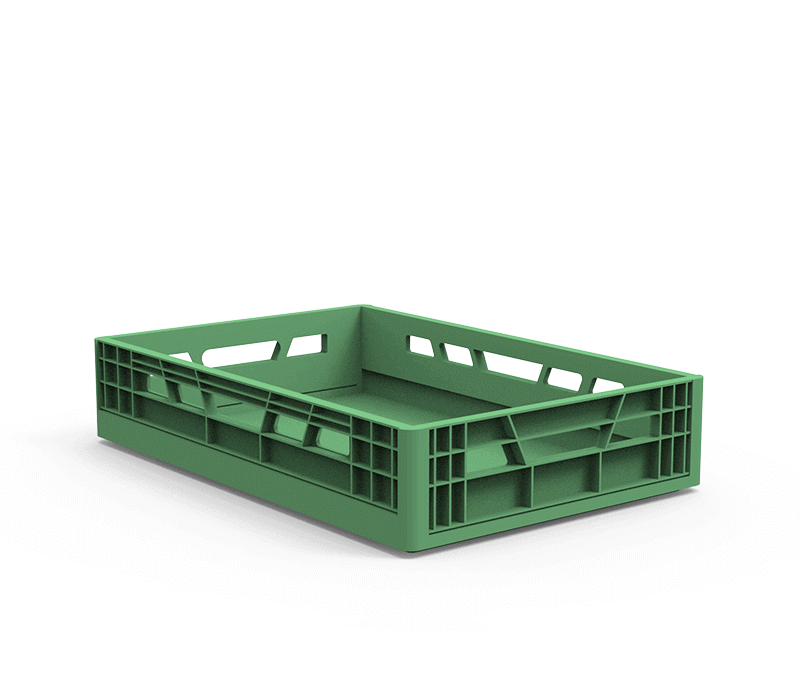

- Customised design and performance for palletising secondary packaging or plastic crates

DESCRIPTION

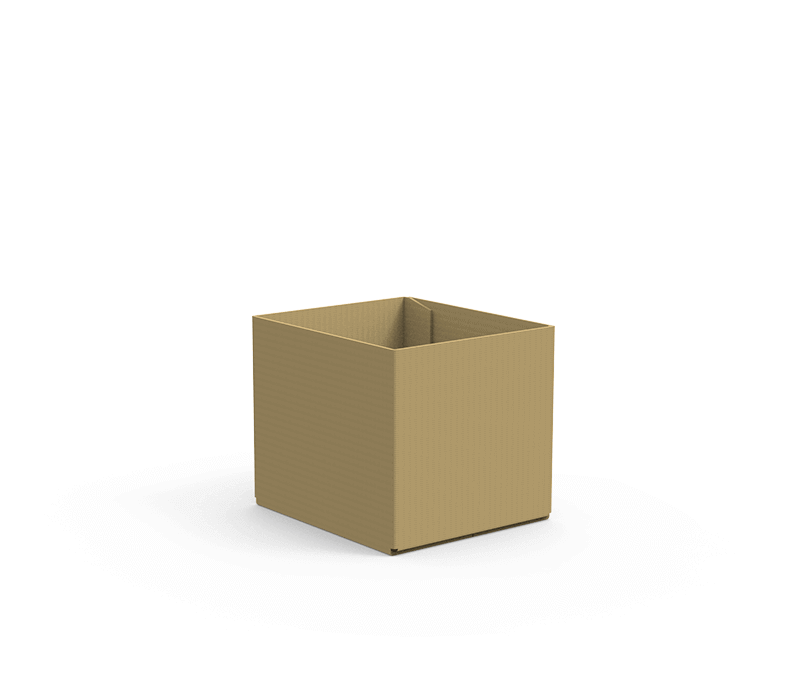

Palletising units used to stack secondary packaging on pallets, with or without inserting interlayers.

The P-10-A series systems transfer the cases automatically from the feeder line and stack them on the pallet in multiple layers according to the pattern defined in the recipe.

Extremely compact and versatile, the robot palletising systems are characterised by a wide range of functions, their reduced footprint and ease of use. Thanks to their modular design, it is possible to optimise the Lay-Out of the system to suit the destination space. This means that the systems may be equipped with automatic pallet magazines with or without separator units, interlayer magazines, pallet labelling rollers, finished pallet wrapping units, angular units and anything else that may be necessary to fully automate the palletization process.

The machines are available with one, two or three palletizing bays in order to process more than one job at a time. Special applications may be realised upon customer request.

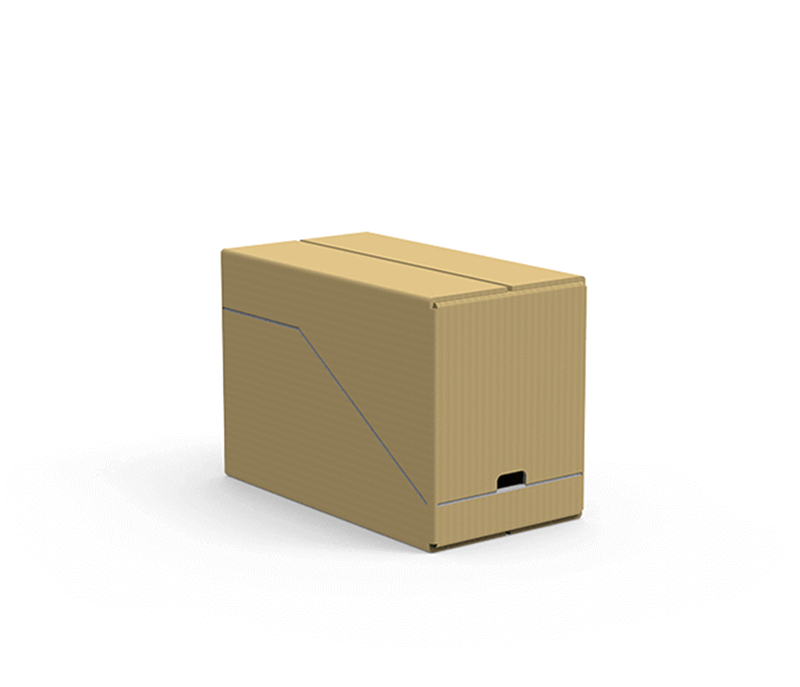

The P-10-A series systems are equipped with case pick-up head, operated by brushless motors, and, if necessary, they may also be supplied with a pneumatic extractor to safeguard packaging held by lids. Rather than exploiting the friction created between the pick-up flaps and the lateral panels of the packaging, the manipulator heads employ a system that enables them to lift the cases by their base.

Programming new recipes is simple and intuitive thanks to the standard 15” touch screen control panel.

ADVANTAGES

- Reduced footprint

- Flexible layout

- Respect of boxes

- Option of pallet-on-pallet palletization

- Hygienic design

- Compatible with a wide range of pallet sizes

- Automatic size changeover does not require use of tools

- Automatic pallet and interlayer magazine

- May be used to process packaging and pallets of differing sizes simultaneously

- Standard 15” control panel with 3D graphics

- Customisable upon request

- Available with a wide range of additional modules

TECHNICAL SPECIFICATIONS

TECHNICAL DATA – SPECIFICATIONS

| Pack Dimensions (LxWxH) | Min 150x80x80 – Max 600x400x350 |

| Pallet dimensions | – EUPAL 80 x 120 – INDUSTRY 100 x 120 |

| Robot operating speed | Up to 550 cycles/hour |