Lidding Unit

- Automatic solution for placing lids on standard half cases, plateaus or open blank display trays

DESCRIPTION

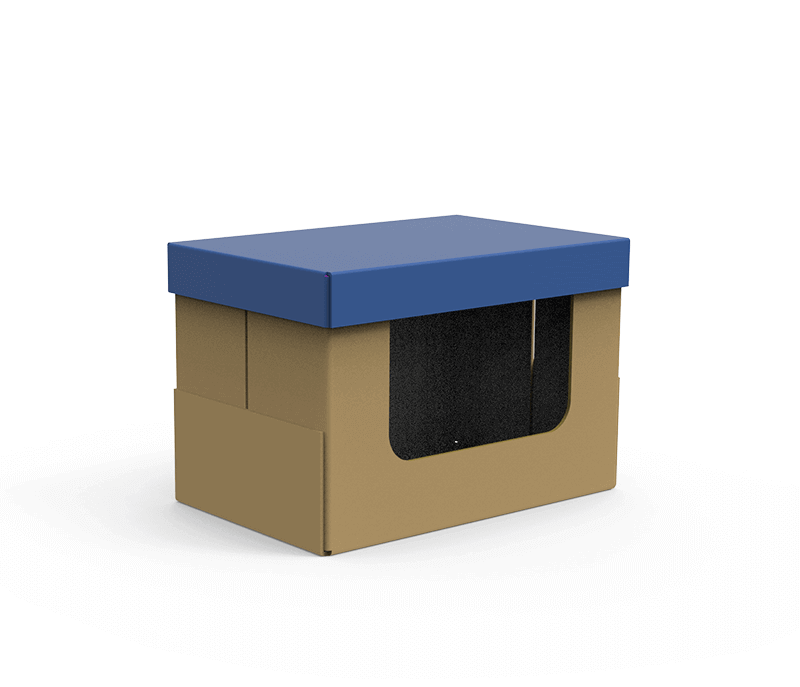

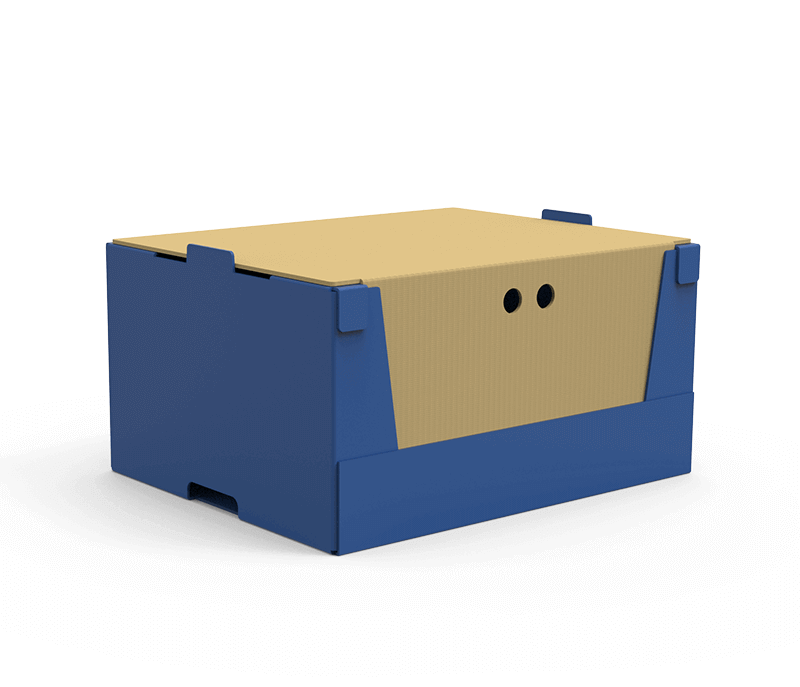

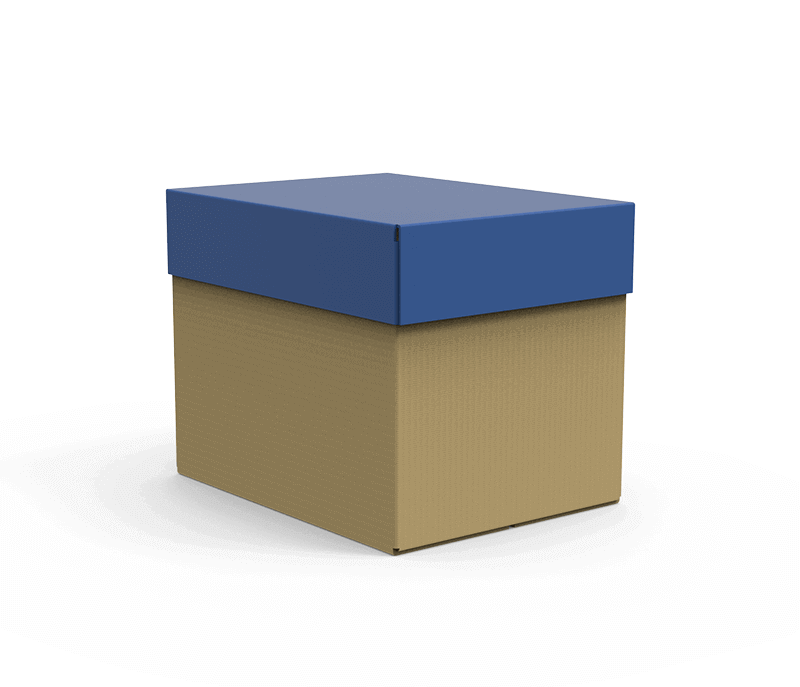

A series of machines designed to fit lids automatically on standard half cases, plateaus or open blank display trays.

Thanks to their versatility, these units may be used to produce display trays with internal or external lids.

Special applications may be realised upon customer request. The machines include conformity checks on the packs at the infeed and the lidded packs at the outfeed.

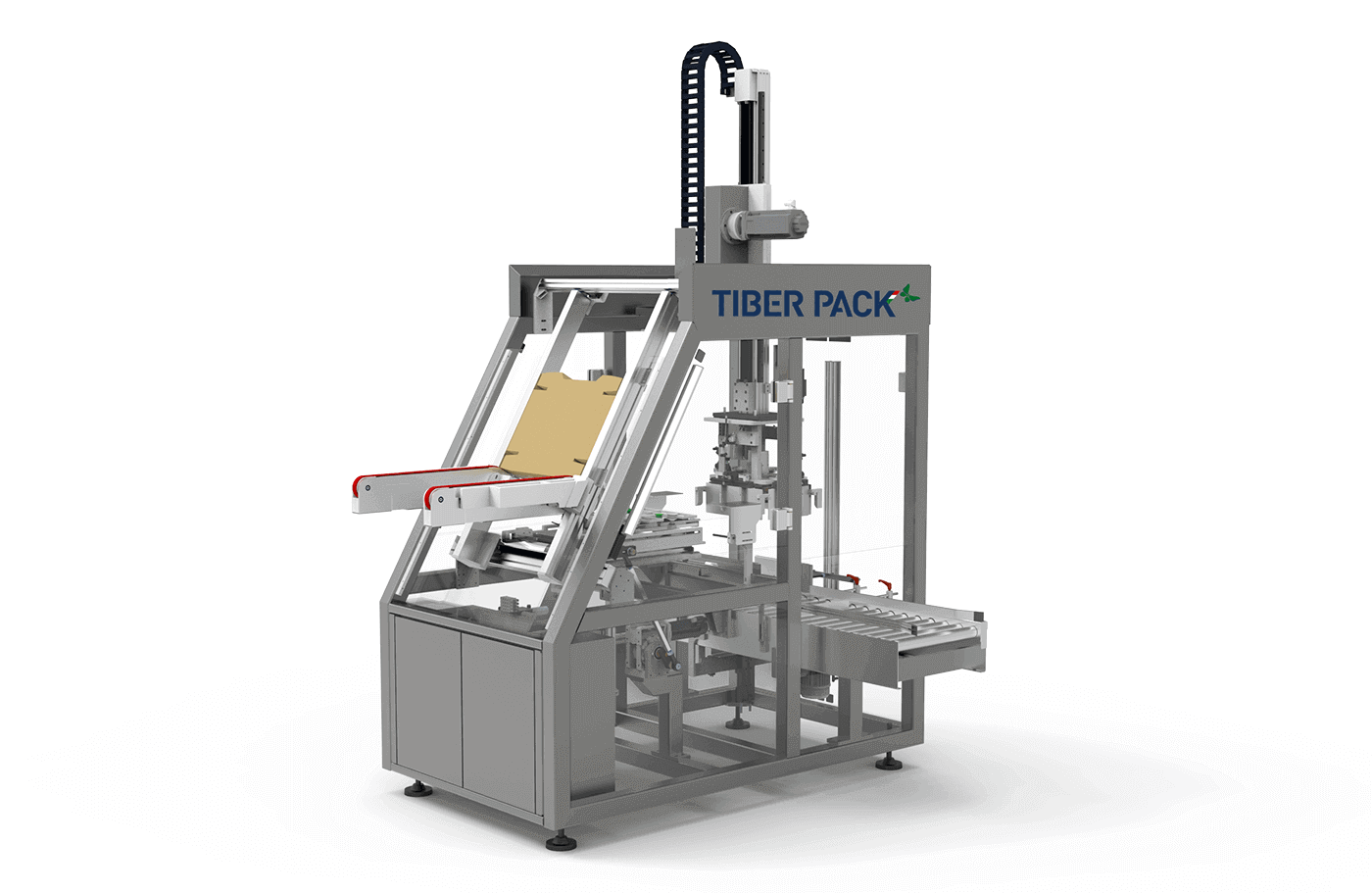

Extremely compact and versatile, COP-E lidding units are characterised by a wide range of functions, their reduced footprint and ease of use. They are equipped with a large, easy to load, fully self-regulating magazine. Easy to access, they are both ergonomic and intuitive.

The COP-E series lidding units may be equipped with a hot-melt lid gluing module and numerous other accessories, so that can be adapted to the customer’s specific requirements.

The stand-alone version is supplied with a HMI interface complete with a 15” touch screen control panel.

When it is necessary to position them physically close to the package forming and filling module, the lidding units may be integrated into the upstream line electrical system using the same control panel, the same operator panel and the same gluing unit.

ADVANTAGES

- Reduced footprint

- Flexible layout

- Tray and lid secure hot-melt optionHygienic design

- Compatible with a wide variety of lid shapes

- Automatic, tool-less size changeover

- Large capacity blanks magazine

- Standard 15” touch control panel with 3D graphics

- Customisable upon request

- Available with a wide range of additional modules

TECHNICAL SPECIFICATIONS

TECHNICAL DATA – SPECIFICATIONS

| Lid Dimensions (LxWxH) | Min 150x100x40 – Max 600x400x300 |

| Lid sealing type | Hot-Melt |

| Capacity | Up to 20 lids/minute |