Filling unit with 6 axis robot

- Customised design and performance for palletising secondary packaging or plastic crates

- Suitable for use with rigid or flexible packaging

DESCRIPTION

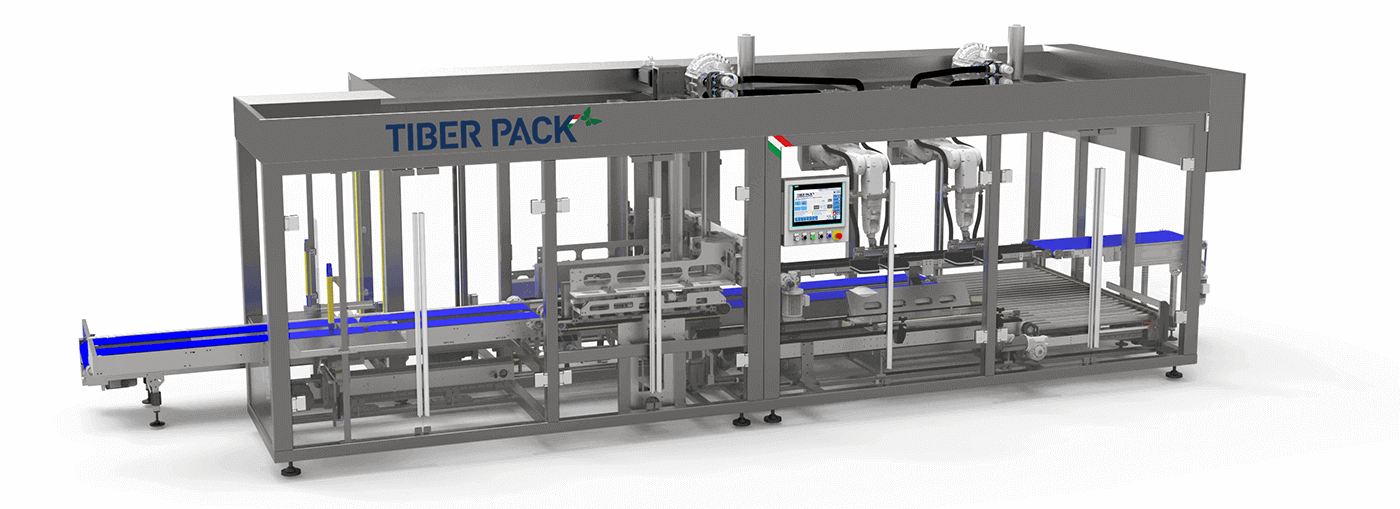

Automatic machine for filling preformed cardboard cases or plastic crates, capable of manipulating both rigid and flexible packs. These machines may be combined with forming and closing modules to form complete modular lines. They may also be coupled with fully self-regulating empty case destacker and full case stacker modules.

The BFP series filling solutions may be used to place the packs in their packaging, placing them vertically or horizontally, according to a variety of configurations. Special applications may be realised upon customer request. The machines include conformity checks on the products at the infeed and the packs at the outfeed.

Extremely compact and versatile, BFP Filling units are characterised by a wide range of functions, their reduced footprint and ease of use. As well as their ergonomic design and standard, intuitive 15” HMI panel, they are also characterised by their high accessibility.

The BFP Filling units may be equipped with either the horizontal or the vertical products module, or both modules together for maximum multi-functionality. Thanks to the high payload of the robots, the filling machine may be equipped with rotary vacuum pump and used to process packs weighing in excess of 3 kg.

They may also be equipped with automatic size changeover and a wide range of accessories, meaning that that they are highly customisable based on the client’s specifications

ADVANTAGES

- Reduced footprint

- Flexible layout

- High performance and respect for product

- Hygienic design

- Flexibility of product layout inside packaging

- Suitable for use with a wide variety of products and primary packaging

- Automatic, tool-less size changeover

- Standard 15” control panel with 3D graphics

- Customisable upon request

- Available with a wide range of additional modules

- Modular machine

TECHNICAL SPECIFICATIONS

TECHNICAL DATA – SPECIFICATIONS

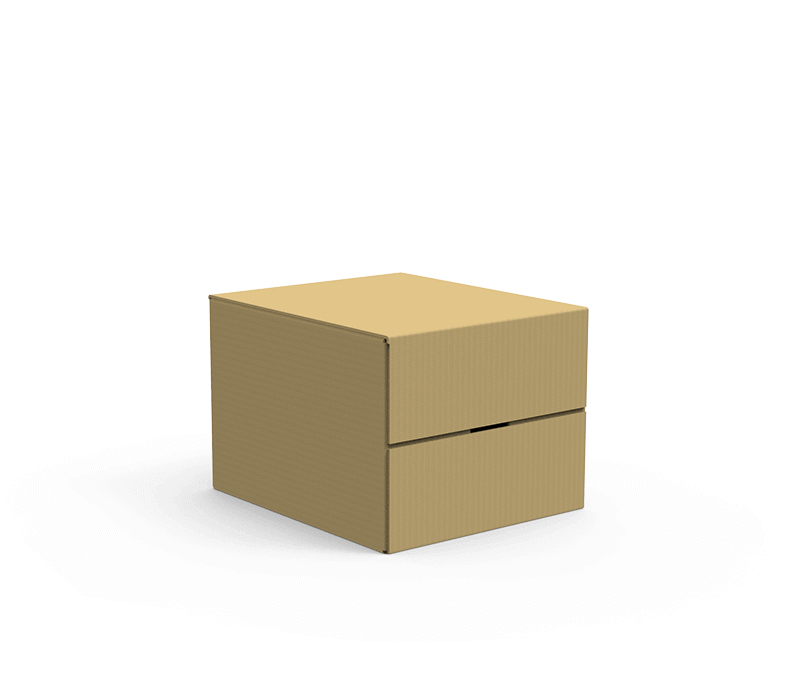

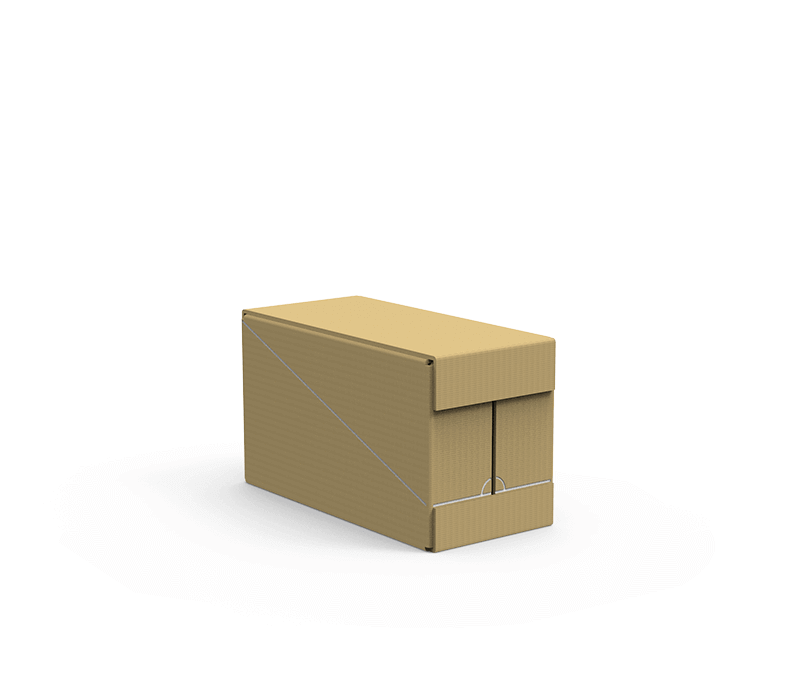

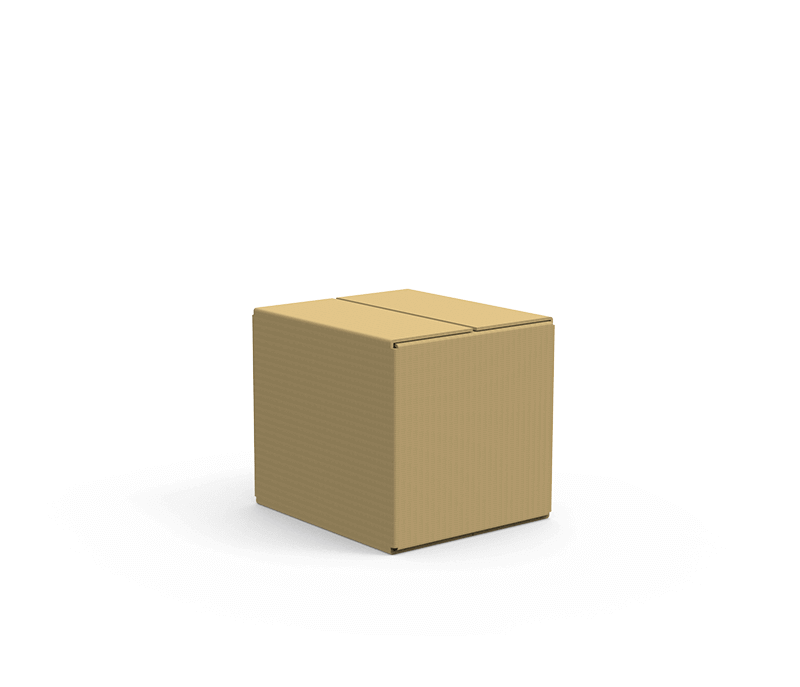

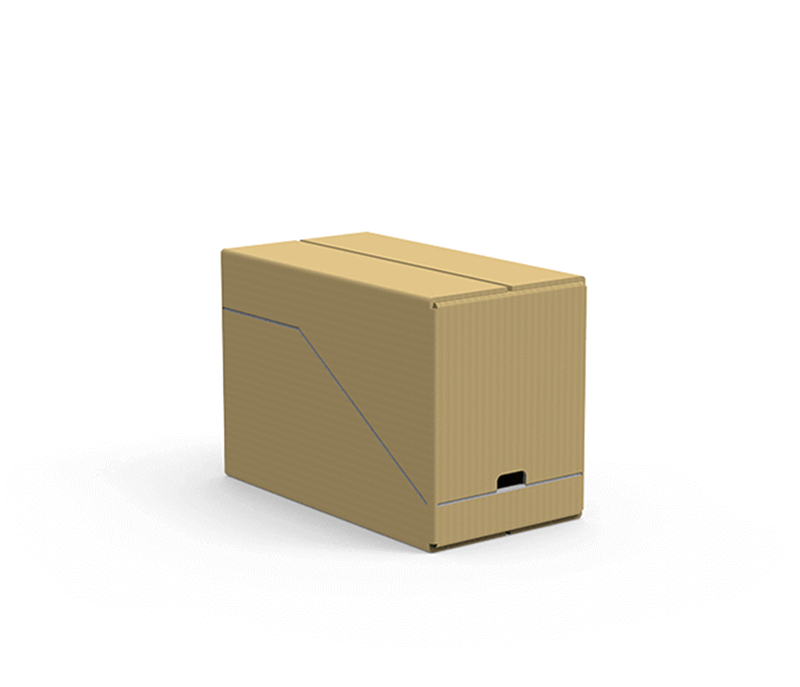

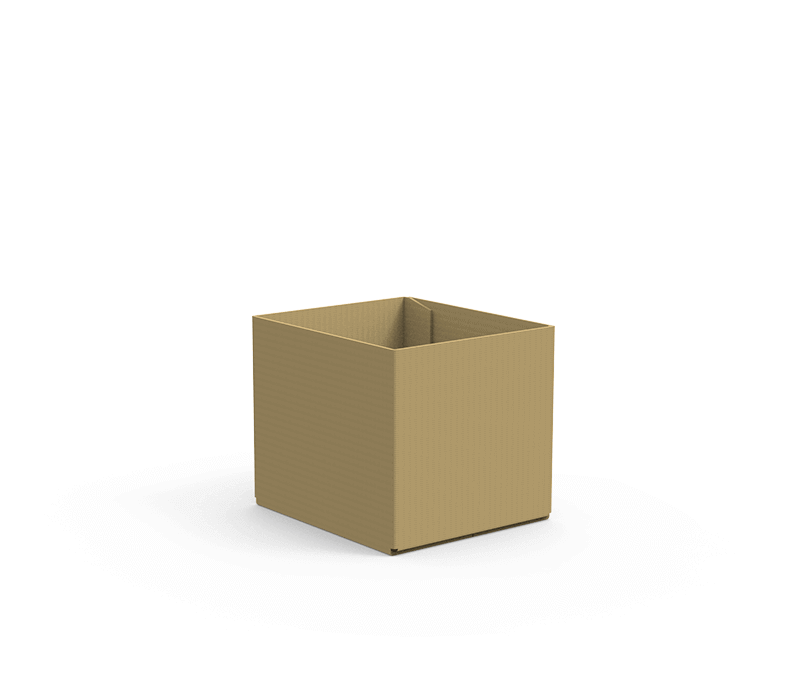

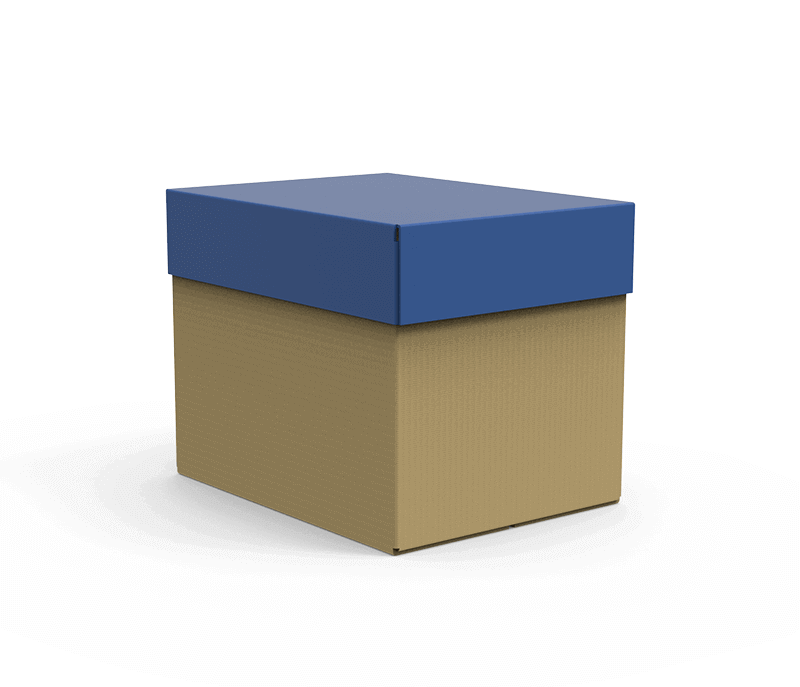

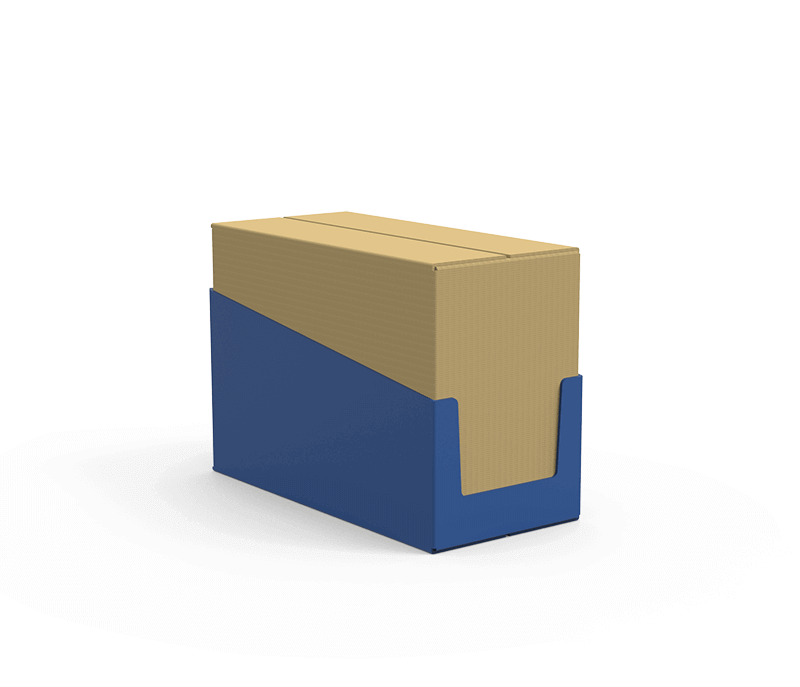

| Pack Dimensions (LxWxH) | Min 150x80x80 – Max 600x400x350 |

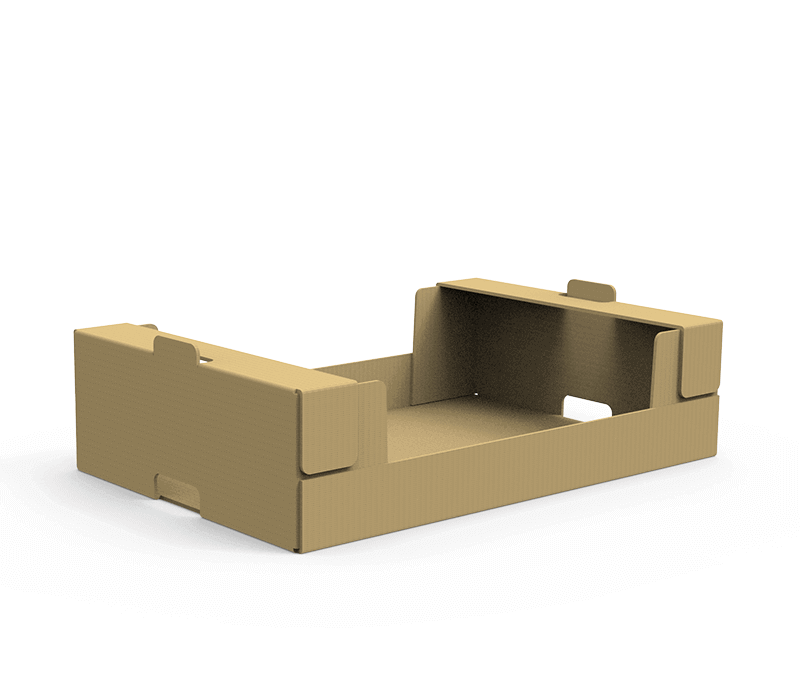

| Product mosaic inside the case | – Placed vertically/side-by-side – Placed horizontally |

| Product infeed capacity | Up to 75 per minute |

| Pack filling capacity | Up to 10 packs/minute |

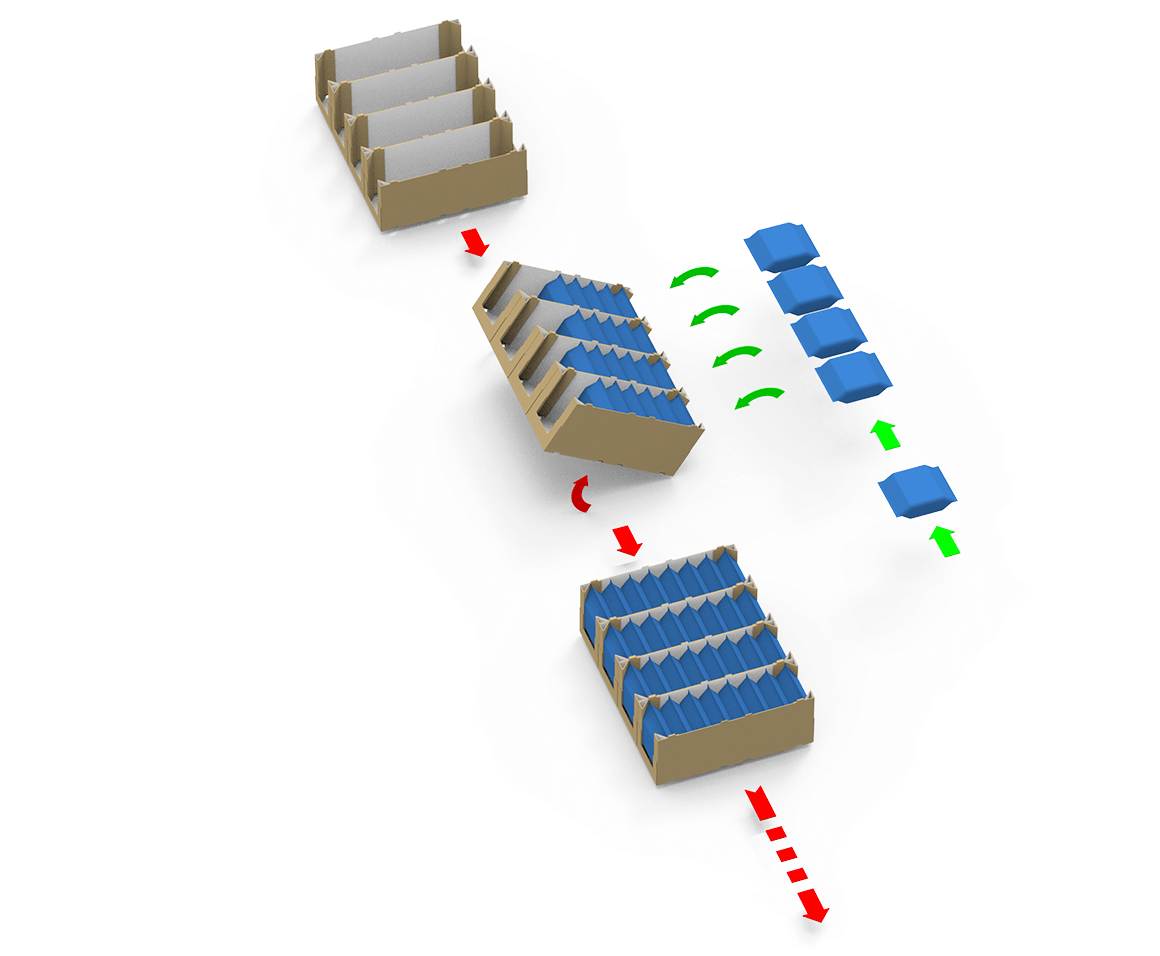

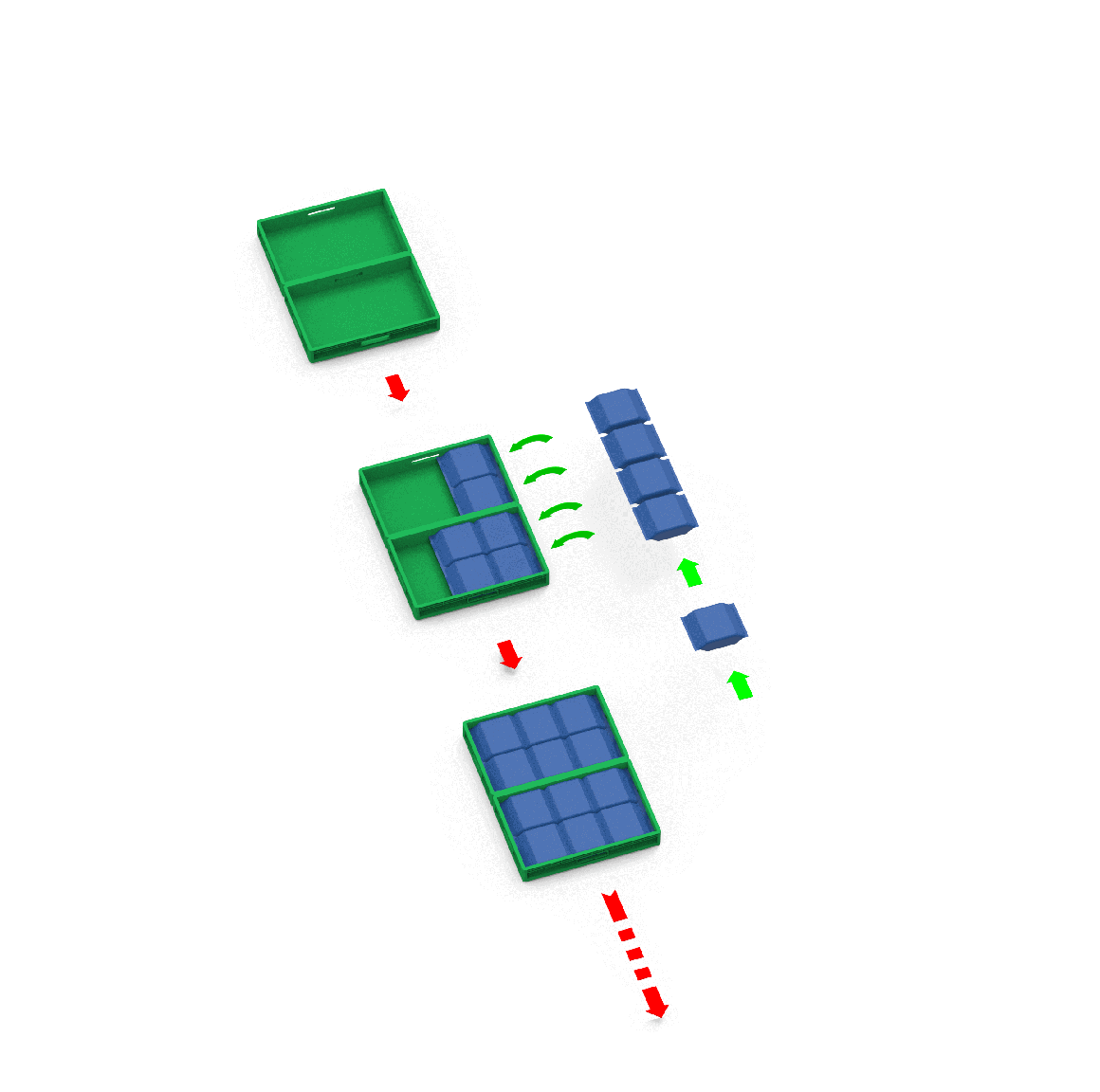

WORK FLOW CAPTIONS

The BFP series solutions may be used to place the packs inside the packaging either vertically or horizontally according to a wide range of patterns.

Both operating modes are possible on the same system, thanks to the quick, intuitive size changeover system.

The operating concept may be customised so as to adapt it better to your products and packaging needs.